AIR FRAME INTEGRATED SCRAMJET ENGINE INLET CONFIGURATION

1. INTRODUCTION

1.1 GENERAL

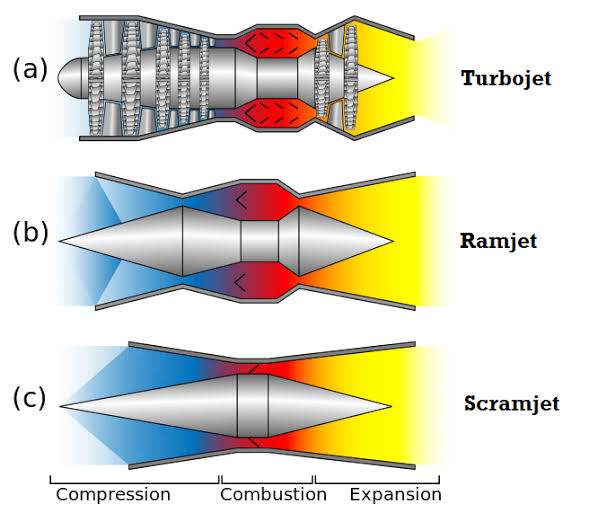

A scramjet (supersonic

combustion ramjet) is a variant of a ramjet air-breathing combustion jet engine

in which the combustion process takes place in supersonic airflow. As in

ramjets, a scramjet relies on high vehicle speed to forcefully compress and decelerate

the incoming air before combustion (hence ramjet), but whereas a ramjet

decelerates the air to subsonic velocities before combustion, airflow in a

scramjet is supersonic throughout the entire engine.

This allows the scramjet to efficiently operate at hyper-sonic speeds (Mach >5) theoretical projections place the top speed of a scramjet between Mach 12 and Mach 24, which is near orbital velocity. An airframe-integrated scramjet is basically composed of three basic components: a converging air intake, where incoming air is compressed and decelerated; a combustion, where gaseous fuel is burned with atmospheric oxygen to produce heat; and a diverging nozzle, where the heated air is accelerated to produce thrust.

1.2 DEFINITION OF A SCRAMJET ENGINE

In order

to provide the definition of a scramjet engine, the definition of a ramjet

engine is first necessary, as a scramjet engine is a direct descendant of a

ramjet engine.

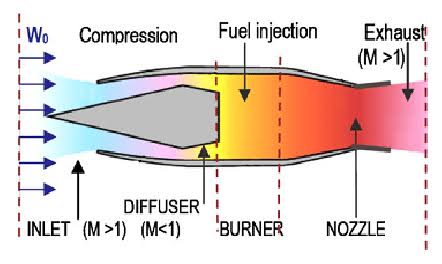

Ramjet

engines have no moving parts, instead operating on compression to slow

freestream supersonic air to subsonic speeds, thereby increasing temperature

and pressure, and then combusting the compressed air with fuel. Lastly, a

nozzle accelerates the exhaust to supersonic speeds, resulting in thrust.

Figure 1 below shows a two-dimensional schematic of a ramjet engine.

Fig 1.2

TWO-DIMENSIONAL SCHEMATIC OF A

RAMJET ENGINE

Due to the deceleration of the

freestream air, the pressure, temperature and density of the flow entering the burner

are considerably higher than in the freestream. At flight Mach numbers of

around Mach 6, these increases make it inefficient to continue to slow the flow

to subsonic speeds. Thus, if the flow is no longer slowed to subsonic speeds,

but rather only slowed to acceptable supersonic speeds, the ramjet is then

termed a

Though the concept of ramjet and

scramjet engines may sound like something out of science fiction, scramjet

engines have been under development for at least forty years. The following

subsection will give a brief chronological history of the scramjet engine.

1.3 SCRAMJET ENGINE HISTORICAL TIMELINE

It is the intention of this section to provide a

brief introduction to the historical timeline of the scramjet, so as to provide

a knowledge base for the current project. There have been many authors that

have provided more thorough historical accounts of both the ramjet and scramjet

this section only seeks to list the highlights of the scramjet‟s development

here.

As mentioned previously, the scramjet is a direct

descendant of the ramjet. Therefore, in an attempt to provide a brief

historical timeline of the modern-day scramjet, we must first begin with the

invention of the ramjet. The first patent for a subsonic ramjet device,

specifically for what is now

Unfortunately, this program was

not able to be flight tested as the cost to repair the X-15 A-2 was too high

and the entire X-15 program was cancelled in 1968 . (Note: The damage referred

to here occurred during the first non-burning test flight when the shock wave

from the inlet spike impinged on the lower ventral fin, causing extensive

damage one of the first incidents of shock-shock interaction heating, which

became a major

In summary, the major propulsion

systems of the modern era have a direct correlation between the year of their

first flight and their current prevalence of application: Turbojet-1939,

Ramjet-1940, High-Performance Large Liquid-Fueled Rocket Engine-1943, Practical

Man-Rated Reusable Throttleable Rocket Engine-1960, and the Scramjet-2002.

However, despite the fact that no operational and readily available scramjet

engine currently exists, this is not due to a lack of potential applications

which would benefit greatly from the use of the scramjet.

1.4 DESIGN PRINCIPLE OF A

SCRAMJET ENGINE

Scramjet

engines are a type of jet engine, and rely on the combustion of fuel and an

oxidizer to produce thrust. Similar to conventional jet engines,

scramjet-powered aircraft carry the fuel on board, and obtain the oxidizer by

the ingestion of atmospheric oxygen (as compared to rockets, which carry both fuel and an oxidizing agent). This requirement limits scramjets to suborbital atmospheric propulsion

where the oxygen content of the air is sufficient to maintain combustion.

The scramjet is composed of three basic components: a converging inlet, where

incoming air is compressed; a

combustor, where gaseous fuel is burned with atmospheric oxygen to produce heat; and a diverging nozzle, where the heated

air is accelerated to produce thrust. Unlike a typical jet engine, such as a turbojet or turbofan engine, a scramjet does not use rotating, fan-like

components to compress the air; rather, the achievable speed of the aircraft

moving through the atmosphere causes the air to compress within the inlet. As

such, no moving parts are needed in a scramjet. In comparison, typical turbojet

engines require inlet fans, multiple

stages of rotating compressor

fans, and multiple rotating turbine stages, all of which add weight, complexity, and a greater number of

failure points to the engine.

Due to the nature of their design, scramjet operation is limited to near-hypersonic velocities. As they lack mechanical compressors, scramjets require the high kinetic energy of a hypersonic flow to compress the incoming air to operational conditions. Thus, a scramjet-powered vehicle must be accelerated to the required velocity (usually about Mach 4) by some other means of propulsion, such as turbojet, railgun, or rocket engines. In the flight of the experimental scramjet-powered Boeing X-51A, the test craft was lifted to flight altitude by a Boeing B-52Stratofortress before being released and accelerated by a detachable rocket to near Mach 4.5. In May 2013, another flight achieved an increased speed of Mach 5.1

Due to the nature of their design, scramjet operation is limited to near-hypersonic velocities. As they lack mechanical compressors, scramjets require the high kinetic energy of a hypersonic flow to compress the incoming air to operational conditions. Thus, a scramjet-powered vehicle must be accelerated to the required velocity (usually about Mach 4) by some other means of propulsion, such as turbojet, railgun, or rocket engines. In the flight of the experimental scramjet-powered Boeing X-51A, the test craft was lifted to flight altitude by a Boeing B-52Stratofortress before being released and accelerated by a detachable rocket to near Mach 4.5. In May 2013, another flight achieved an increased speed of Mach 5.1

1.5 BASIC PRINCIPLE OF A SCRAMJET ENGINE

Scramjets are designed to operate in the hypersonic flight regime, beyond the reach of turbojet engines, and, along with ramjets, fill the gap between the high efficiency of turbojets and the high speed of rocket engines. Turbo machinery based engines, while highly efficient at subsonic speeds, become increasingly inefficient at transonic speeds,as the compressor fans found in turbojet engines require subsonic speeds to operate.While the flow from transonic to low supersonic speeds can be decelerated to these conditions, doing so at supersonic speeds results in a tremendous increase in temperature and a loss in the total pressure of the flow.

Around Mach 3–4, turbomachinery is no longer

useful, and ram-style compression becomes the preferred method.Ramjets utilize

high-speed characteristics of air to literally 'ram' air through an inlet diffuser

into the combustor. At transonic and supersonic flight speeds, the air upstream

of

Fig 1.4 SCRAMJET ENGINE OPERATION

2. PROBLEM STATEMENT

2.1 PROBLEM DEFINITION

This chapter will provide the problem description as

well as the background theory and equations necessary to address the problem at

hand.

The above fig shows the reference geometry for our

simulation analysis. The model is already predefined by the author AUGUSTO F. MOURA, MAURÍCIO A. P. ROSA Instituto de Estudos Avançados (IEAv) Departamento de Ciência e

Tecnologia Aeroespacial

A scramjet (supersonic combusting ramjet) is a variant of a ramjet air breathing jet engine in which combustion

takes place in supersonic airflow. As in ramjets, a scramjet relies on high vehicle speed to

forcefully compress the incoming air before combustion (hence ramjet), but a ramjet decelerates the

air to subsonic velocities before combustion, while airflow in a scramjet is supersonic throughout

the entire engine. This allows the scramjet to operate efficiently at extremely

high speeds.

3. LITERATURE REVIEW

These geometric changes have produced a numerous shocks in inlet and remarkable influence on the flow in several aspects. However, the performance of these inlets tends to degrade as higher Mach number to lower Mach number. These inlets consisting of various ramps producing oblique shocks followed by a cowl shock is chosen in order to increase air mass capture and reduce spillage in scramjet inlets at Mach numbers below the design value. An impinging shock may force the boundary layer to separate from the wall, resulting in total pressure recovery losses and a reduction of the inlet efficiency. Design an inlet to meet the requirements such as Low stagnation pressure loss, High static pressure and temperature gain and deceleration of flow to a desired value of Mach number. Fixed geometry inlets can be used only over a relatively narrow range of Mach number while one method to improve this performance is to use variable-geometry inlets which can be used over a wide range of Mach number with reasonably good pressure recovery. A two dimensional analysis is carried out in this project. CATIA is used to create the model. GAMBIT is used to create the mesh. FLUENT is used to cover the flow analysis.

The following discretization scheme have been used within the project

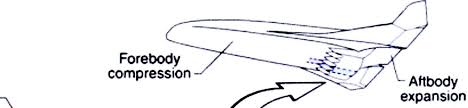

This study

is concerned basically with the air intake system of an airframe-integrated

scramjet engine, which is consisted of the vehicle forebody, the engine inlet

and the isolator duct (see Fig.1). Although many times the isolator duct, which

is located between the scramjet inlet and the combustor, is not included in

analyses of the compression system, here it was considered because of the

interest in knowing the airflow conditions at the combustor entrance. The

isolator has the main purpose of protecting the inlet from combustor high

pressure effects (adverse back pressure), although, in some situations, it also

contributes to the compression process. Efficient combustion of fuel requires

that supersonic airflow be supplied to the combustor at suitable pressure,

temperature and flow rate. In a hypersonic vehicle with scramjet propulsion it

is the air intake system that has this task.

2.2 PROPOSED SOLUTION

The

work aims to present numerical simulations and performance analyses of a

scramjet air intake configuration being tested for the 14-X scramjet engine

when the vehicle operates at different flight speeds, altitudes and angles of

attack. Besides, analyses have also been made for geometry deviations from the

reference configuration, in terms of the number and angle of the intake ramps.

For the numerical calculations, it has been considered 2D planar geometry and

the calorically perfect gas and non-viscous models for the airflow. The goal is

to have a better insight on the flow behavior in the air intake region of the

propulsion system when changing flight parameters such as speed, angle of

attack and altitude, for the reference configuration, and also to study the

impact of intake geometry changes on the overall intake performance.

3.1 DESIGN AND ANALYSIS ON SCRAMJET ENGINE INLETAQHEEL

MURTUZA SIDDIQUI1,

G.M.SAYEED AHMED

Research

Assistant, Muffakham Jah College of Engineering & Technology.,

Hyderabad-5000342 Senior Assistant professor, Muffakham Jah

College of Engineering& Technology., Hyderabad-500034 carried out The

scramjet is composed of three basic components: a converging inlet, where

incoming air is compressed and decelerated; a combustor, where gaseous fuel is

burned with atmospheric oxygen to produce heat; and a diverging nozzle, where

the heated air is accelerated to produce thrust. Unlike a typical jet engine,

such as a turbojet or turbofan engine, a scramjet does not use rotating,

fan-like components to compress the air; rather, the achievable speed of the

aircraft moving through the atmosphere causes the air to compress within the

inlet. As such, no moving parts are needed in a scramjet. In comparison,

typical turbojet engines require inlet fans, multiple stages of rotating

compressor fans, and multiple rotating turbine stages, all of which add weight,

complexity, and a greater number of failure points to the engine. The parts

described above can be seen in Figure below.

Due to the nature of their design, scramjet operation

is limited to near-hypersonic velocities. As they lack mechanical compressors,

scramjets require the high kinetic energy of a hypersonic flow to compress the

incoming air to operational conditions. Thus, a scramjet powered vehicle must

be accelerated to the required velocity by some other means of propulsion, such

as turbojet, railgun, or rocket engines. While scramjets are conceptually

simple, actual implementation is limited by extreme technical challenges.

Hypersonic flight within the atmosphere generates immense drag, and

temperatures found on the aircraft and within the engine can be much greater

than that of the surrounding air. Maintaining combustion in the supersonic flow

presents additional challenges, as the fuel must be injected, mixed, ignited,

and burned within milliseconds. While scramjet technology has been under

development since the 1950s, only very recently have scramjets successfully

achieved powered flight

3.2 A NUMERICAL INVESTIGATION OF

SCRAMJET

ENGINEAIR INTAKES FOR THE 14-X HYPERSONIC VEHICLEAUGUSTO F.

MOURA, MAURÍCIO A. P.ROSA

Instituto de EstudosAvançados(IEAv)

Departamento de Ciência e Tecnologia Aeroespacial TrevoCel. Aviador José

Alberto Albano do Amarante, São José dos Campos,Brasil carried outpar tofthe

research and development, at the Institute for Advanced Studies (IEAv), of the

first Brazilian hypersonic vehicle prototype, the 14-X airplane.It presents CFD

results and performance calculations of the air intake section of some scramjet

engine configurations under several operating conditions assuming 2D planar

geometry. The reference case considers the vehicle flying at Mach 7 and zero

angle of attack at an altitude of 30km. In thi scase, air compression is

achieved by two ramps,one of which is the vehicle forebody itself and the other

is a scramjet inlet compression ramp, and the engine cowl which satisfies

the“shock-onlip”condition. From this reference case,several other cases were

simulated varying vehicle operating conditions such as altitude, velocity and

angle of attack. Besides these, calculations were made for different

configurations of the scramjet inlet compression geometry by varying the inlet

compression ramp angle, as well as the number of inlet compression ramps. The

airflow in the intake is calculated numerically with the commercial Ansys

Fluent software, considering the air as a calorically perfect gas for inviscid

flow. For the intake performance analysis, several parameters characterizing

the intakes have been calculated and compared.

3.3 COMPUTATIONAL ANALYSIS OF SCRAMJET INLET

Murugesan,

Dilip A Shah and Nirmalkumar IndiaScramjet inlets are the most vital component

of the engine and their design having more effective on the overall performance

of the engine. Thus, the forward capture shape of the engine inlet should

conform to the vehicle body shape. A 2-D computational study for scramjet inlet

with different ramp length and angles are studied to compress the air by

blunted and sharp leading edge, moving the whole cowl up and down, deflecting

the cowl lip and axisymmetric inlet with sharp and blunted leading edge.

These geometric changes have produced a numerous shocks in inlet and remarkable influence on the flow in several aspects. However, the performance of these inlets tends to degrade as higher Mach number to lower Mach number. These inlets consisting of various ramps producing oblique shocks followed by a cowl shock is chosen in order to increase air mass capture and reduce spillage in scramjet inlets at Mach numbers below the design value. An impinging shock may force the boundary layer to separate from the wall, resulting in total pressure recovery losses and a reduction of the inlet efficiency. Design an inlet to meet the requirements such as Low stagnation pressure loss, High static pressure and temperature gain and deceleration of flow to a desired value of Mach number. Fixed geometry inlets can be used only over a relatively narrow range of Mach number while one method to improve this performance is to use variable-geometry inlets which can be used over a wide range of Mach number with reasonably good pressure recovery. A two dimensional analysis is carried out in this project. CATIA is used to create the model. GAMBIT is used to create the mesh. FLUENT is used to cover the flow analysis.

Computational Fluid Dynamics or CFD as it is

popularly known, is used to generate flow simulations with the help of

computers. CFD involves the solution of the governing laws of fluid dynamics numerically. The complex set of partial differential equations are solved on in

geometrical domain divided into small volumes, commonly known as a mesh (or grid).CFD has enabled us to understand the world in new ways. We can now see

what it is like to be in a furnace, model how blood flows through our arteries and

veins and even create virtual worlds. CFD enables analysts to simulate and

understand fluid flows without the help of instruments for measuring various

flow variables at desired locations.

Fluent is the CFD solver which can handle both structured grids, i.e. rectangular grids with clearly defined

node indices, and unstructured grids. Unstructured grids are generally of

triangular nature, but can also be rectangular. In 3-D problems, unstructured

grids can consist of tetrahedral (pyramid shape), rectangular boxes, prisms,

etc

4.2 Finite - volume approach

The commercial code Fluent solve

the governing integral equations for the conservation of mass and momentum, and

(when appropriate) for energy and other scalars, such as turbulence and

chemical species. In both cases a control-volume-based technique is used which

consists of,

·

Division of the domain into

discrete control volumes using a computational grid

· Integration of the governing

equations on the individual control volumes to construct algebraic equations

for the discrete

· Linearization

of the discretion equations and solution

of the resultant linear equation system, to yield updated values of the Fluent is a commercial 2D/3D unstructured mesh

solver, which adopts Multigrid solution algorithms. It uses a co-located grid,

meaning that all flow parameters are stored in the cell-centers.

Two numerical methods are available in Fluent:

Two numerical methods are available in Fluent:

·

Pressure-based solver

·

Density-based solver

The first

one was developed for low-speed in compressible flows, whereas the second was

created for the high-speed compressible flows solution. Although they have been

recently modified in order to operate for a wider range of flow conditions, in

the present study, which involves in compressible flows, the pressure-based

approach was preferred

Pressure

based solver

In the

pressure-based approach the pressure field is obtained by solving a pressure

correction equation, which results from combining continuity and momentum

equation. i.e., the pressure equation is derived in such a way that the

velocity field, corrected by the pressure, satisfies the continuity. The

governing equations are non-linear and coupled one another. The solution

process involves therefore iterations, wherein the entire set of governing

equations is solved repeatedly, until the solution converges.

Two types

of solution algorithms are available in Fluent:

· Segregated · Coupled

The segregated

pressure-based solver uses a solution algorithm

Where

the governing equations are solved sequentially (i.e., segregated) from one

another. The segregated algorithm is memory-efficient, since the discretized

equations need only be stored in the memory one at a time. However, the

solution convergence is relatively slow, inasmuch as the equations are solved

in a decoupled manner.

Pressure-Velocity

Coupling

Solution of

Navier-Stokes equation is complicated even because of the lack of an

independent equation for the pressure, whose gradient contribute to each of the

three momentum equations. Moreover, for incompressible flows like we have been

dealing with, the continuity equation does not have a dominant variable, but it

is rather a kinematic constraint on the velocity field. Thus, the pressure

field (the pressure

4.3 Discretization scheme

The following discretization scheme have been used within the project

·

First-Order

Upwind scheme

·

Second-Order

Upwind scheme

·

QUICK

scheme

The temporal discretization used for unsteady computations was

first order accurate. For pressure interpolation, the schemes adopted were the

default interpolation, which computes the face pressure using momentum equation

coefficients and the PRESTO (PREssure Staggering Option). The first procedure

works well as long as the pressure variation between cell centres is smooth.

When there are jumps or large gradients in the momentum source terms between

control volumes, the pressure profile has a high gradient at the cell face, and

cannot be interpolated using this scheme. Flows for which the standard pressure

interpolation scheme will have trouble include flows with large body forces,

such as in strongly swirling flows, natural convection and the like. In such cases,

it is necessary to pack the mesh in regions of high gradient to resolve the

pressure variation adequately. Another source of error is that Fluent assumes

the normal pressure gradient at the

4.4 Defining Boundary Conditions

Boundary

conditions (BCs) specify the flow variables on the boundaries of the chosen

physical model. They are therefore a critical component of a simulation, and it

is important they are specified appropriately. The utilized boundary conditions

follows, named as reported in the next chapters.

· Wall (no-slip)

Wall

boundary condition is used to bound fluid and solid regions, for instance the

blade surface in a wind turbine model. The no-slip condition is the default

setting for viscous flows and the shear-stress calculation in turbulent flows

follows the adopted turbulent model.

- Velocity-Inlet

Velocity inlet boundary conditions are used to

define the flow velocity, along with all relevant scalar properties of the

flow, at flow inlets. This BC is suitable for in compressible flows, whereas for

compressible flows will lead to a non-physical result because stagnation conditions

are floating. It is possible so set both constant and variable parameters, as

well as they can be alternatively uniform or non-uniformly distributed along

the boundary itself.

- Pressure-Outlet

It

means that a specific static pressure at outlet is set, and allows also a set

of backflow conditions to minimize convergence difficulties Symmetry.

It

is the analogous of a zero-shear slip wall in viscous flow. Zero normal

velocity is at a symmetry plane and zero normal gradients of all variables

exist there as well.

4.5

Post-processing

Fluent allows a complete post-processing of

solution data. Most of them are below. Moreover, the solution data can be

easily exported in a number of common file formats, to be analysed with other

post-processing tools.

·

Domain and grid visualization

·

Vectorial plots of solution

variables

·

Linear, surface, volume integrals

·

Iso-level and contour plots of

solution variables, within selected domain zones

·

Drawing two-dimensional and

three-dimensional plots

·

Tracking path-lines, stream

traces, etc.

Computational Fluid Dynamics (CFD) is the branch of

fluid dynamics providing a cost-effective means of simulating real flows by the

numerical solution of the governing equations. The governing equations for

Newtonian fluid dynamics, namely the Navier-Strokes equations, have been known

forever 150 years.

This chapter explains the turbulent and heat

transfer numerical models used in the present study. The governing equations

and boundary conditions for all studies are presented in this section. The

domain is separated into small cells to form a volume mesh (or grid) using the

program GAMBIT and algorithms in FLUENT are used to

However,

the development of reduced forms of these equations is still an active area of

research, in practical, the turbulent closure problem of the Reynolds-averaged

Navier-strokes equations. For non-Newtonian fuid dynamics, chemically reacting

flows and two phase flows, the theoretical development is at less advantage

stage

Experimental

methods has played an important role in validating and exploring the limits of

the various approximation to the governing equations, particularly wind tunnel

and rig tests that provide a cost-effective alternative to full-scale testing.

The flow governing equations are extremely complicated such that analytic

solutions cannot be obtained for most practical applications. Computational

techniques replace the governing partial differential equations with systems of

algebraic equations that are much easier to solve using computers.

The

steady improvement in computing power, since the 1950‟s,thus has led to the

emergence of CFD. This branch of fluid dynamics complements experimental and

theoretical fluid dynamics by providing cheaper means of testing fluid flow

systems. It also can allow for the testing of conditions which are not possible

or extremely difficult to measure experimentally and are not amenable to

analytic solutions.

Applying

the fundamental laws of mechanics to a fluid gives the governing equations

along with the conservation of energy equation form a set of coupled, nonlinear

partial differential equations. It is not possible to solve these equations

analytically for most engineering problems. However, it is possible to obtain

approximate computer-based solutions to the governing equations for a variety

of engineering problems. This is the subject matter of Computational Fluid

Dynamics

(CFD). There are three components in CFD analysis; the pre-processor, the solver, and the post-processor. Preprocessor is defined as a program that processes input data to produce output that is used as an input to the processor. There are a number of different solution methods which are used in CFD codes. The most common, and the one on which CFD is based is known as the finite volume technique.

(CFD). There are three components in CFD analysis; the pre-processor, the solver, and the post-processor. Preprocessor is defined as a program that processes input data to produce output that is used as an input to the processor. There are a number of different solution methods which are used in CFD codes. The most common, and the one on which CFD is based is known as the finite volume technique.

4.6. WHY TURBULENCE MODEL?

Fluctuations in the velocity field mix transported

quantities such as momentum and energy and cause the transported quantities to

fluctuate as well. These fluctuations can be of a very small scale and

therefore can create extremely large computational expenses for practical

engineering calculations. A modified set

of equations that require much less computational expense are used. This is

done by time-averaging the instantaneous governing equations which then contain

additional unknown variables. Turbulence models are needed to solve these

unknown variables. These models can be classified into two types are, (i) K – ε

and (ii) K – ω.

4.6.1 K-Epsilon TURBULENCE MODEL

The K-Epsilon model has become one of the most

widely used turbulence models as it provides robustness, economy and reasonable

accuracy for a wide range of turbulent flows. Improvements have been made to

the standard model which improves its performance and two variants are available

in Fluent; the RNG (renormalization group) model and the realizable model.

Three versions of the K-Epsilon model will be investigated here. The standard,

RNG, and realizable models have similar form with transport equations for k and

ε. The two transport

The turbulent Prandtl Numbers

governing the turbulent diffusion of k and ε.

The generation and destruction terms in the

equation for ε.

The method of calculating turbulent viscosity.

4.7 SOFTWARE USED

The software‟s used in this project are GAMBIT andFLUENT. GAMBITis

the program used to generate the grid or mesh for the CFD solver whereas

FLUENTis the CFD solver which can handle both structured grids, i.e. rectangular

grids with clearly defined node indices, and unstructured grids. Unstructured

grids are generally of triangular nature, but can also be rectangular. In 3-D

problems, unstructured grids can consist of tetrahedral (pyramid shape),

rectangular boxes, prisms, etc. Fluent is the world's largest provider of

commercial computational fluid dynamics (CFD) software and services. Fluent

covers general-purpose CFD software for a wide range of industrial

applications, along with highly automated, specifically focused packages.

FLUENT is a state-of-the-art computer program for modelling fluid flow and heat

transfer in complex geometries. FLUENT provides complete mesh exibility,

including the ability to solve your own problems using unstructured meshes that

can be generated about complex geometries with relative ease. Supported mesh

types include 2D triangular or quadrilateral, 3D tetrahedral hexahedral pyramid

wedge polyhedral, and mixed (hybrid) meshes. FLUENT is ideally suited for

incompressible and compressible fluid-flow simulations in complex geometries .

Solver

|

Density Based – Explicit Solver

|

|||

Gradient Option

|

Green Gauss – Node Based

|

|||

Turbulence Model Used

|

K-Epsilon (Standard)

|

|||

Boundary Condition

|

Pressure Far-Field and Pressure outlet

|

|||

Gauge (Absolute) Pressure ;

|

6.386 Pa, 223 k

|

|||

Temperature

|

||||

Courant Number

|

0.3

|

|||

All the PDE are solved based on

the

|

Second order Upwind scheme

|

|||

Absolute Criteria for

Convergence

|

1x10-23

|

|||

Material

|

Ideal Gas

|

|||

4.9 REFERENCE VALUES

The Altitude, Mach, Temperature and the corresponding Gauge Pressure

have been taken from the reference journal

Table 4.2 PRESSURE, TEMPERATURE,

DENSITY AND ALTITUDE VALUES

5.1 β AND δ VARIATIONS

Ramp Angle – Considered as Beta, and Del as

specified in the Picture above. We have varied number of Del angles keeping the

Beta (Ramp Angle at 20 Degree constant). And Keeping the Del 10 Degree Constant

Beta has been varied.

Table BASE LENGTH VALUE

CASE

|

PARAMETER

| |

Length

L1

|

657.34

| |

Length

L2

|

330

| |

Simulations have been carried out for various models by changing the

inlet and ramp anglefrom the base geopmetry.

Initially anslysis have been done for the base geometry using the base

reference values for Mach 1.8.

Velocity variations were also studied for the same

model. It was found that the shock is excatly formed at the upper inlet engine

case. Zoomed view of velocity magnitude over thebaseline model is shown in Fig

5.4 at a Mach of 1.8.

5.2 MODEL – 2 – HYPERSONIC INLET WITH DEL 10 DEGREE

Study is done by varying the angles. A new model is

generated having the del angle as 10 keeping the ramp angle constant.

Simulations have been carried out for the geometry at Mach 1.8. Resuts have

been found for pressure and velocity distribution for the model. The below

figures shows the variation of pressure and velocity distribution.

Fig 5.5 shows the generation of mes created for the

model. Triangular and Tetrahedral mesh was created over the geometry to capture

the model for the simulation.

Analysis have

been carried out

for the gometry

with del angle

10.

Simulation

results are shown in the below Figures.

Zoomed simulated view of static pressure over the model with del 10

degree when experiencing Mach 1.8 is shown in Fig 5.6. it is clearly seen that

the shock is formed at both the angles and pressure difference can be studied

from the contour.

Zoomed view of velocity magnitude over the model with del 10 deg when

experiencing mach 1.8 is shown in Fig

5.7

A new case model is studied for various Mach numbers by changing the del

angle as 5 degree. The geometry created is shown in the Fig 5.8.

By keeping the Mach 1.8 pressure and velocity distribution inside the inlet have been studied by comparing with the previous case. It can clealy seen from the simulations results that the compression ration have been increased inside the inlet geometry. This difference is created due to the varaition in the del angle made in the geomtery.

Simulations have been carried out for the model

having del angle as 20 degree at Mach 1.8. the pressure distribution and

velocity variations have been studied.

Simulations have been carried out for the model

having del angle as 20 degree at Mach 1.8. the pressure distribution and

velocity variations have been studied.

Pressure

and velocity variations have been studied for the model.

The Mach number is kept constantn for this case

study.

By keeping the Mach 1.8 pressure and velocity distribution inside the inlet have been studied by comparing with the previous case. It can clealy seen from the simulations results that the compression ration have been increased inside the inlet geometry. This difference is created due to the varaition in the del angle made in the geomtery.

Zoomed view of pressure over the hypersonic inlet

model configuration with del 5 degree when experiencing Mach 1.8. Zoomed view

of velocity magnitude over the hypersonic inlet model configuration with del 5

degree when experiencing Mach 1.8 is shown in Figure 5.10.

5.4 HYPERSONIC INLET

MODEL CONFIG WITH DEL 15 DEGREE GENERATED IN GAMBIT

Here the del angle is varied to 15 degree. The

variation in the geomtery is shown in the Fig 5.11.

Simulations have been carried out for the model

having del angle as 15 degree at Mach 1.8. the pressure distribution and

velocity variations have been studied.

Zoomed view of static pressure over the hypersonic inlet model

configuration with del 15 degree when experiencing Mach 1.8 is shown in Figure

5.12

Simulations have been carried out for the model

having del angle as 20 degree at Mach 1.8. the pressure distribution and

velocity variations have been studied.

Simulations have been carried out for the model

having del angle as 20 degree at Mach 1.8. the pressure distribution and

velocity variations have been studied.

Zoomed view of velocity magnitude over the

hypersonic inlet model configuration with del 15 degree when experiencing Mach

1.8 is shown in Fig 5.13

Zoomed view of static pressure over the hypersonic

inlet model configuration with del 20 degree when experiencing Mach 1.8 is

shown in Fig 5.15

The del angle is varied from 5 degree to 20 degree and analysis have been carried out. For all the cases pressure distribution and velocity variations were studeid.

From the study it is clearly seen that for del angle of 10 degree we have got a good compression ratio. This can be clearly seen from the various pressure and velocity contours shown in the above figures for all cases.

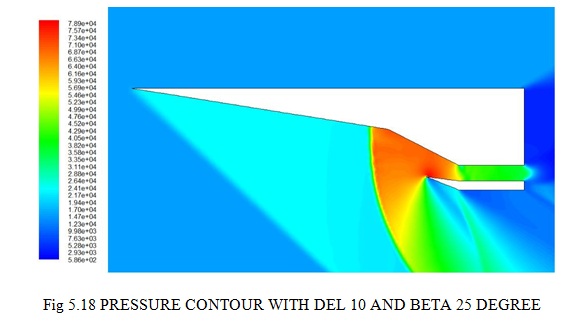

5.6 HYPERSONIC INLET CONFIGURATION WITH DEL 10 DEGREE AND BETA (RAMP ANGLE) 25 DEG GENERATED IN GAMBIT

The next set of study is done by keeping the del

angle constant and varying the ramp angle from 25 degrees to 35 degrees with a

variation of 5 degree at each case.

The Fig 5.17 shows the basic variation of ramp

angle which is started at 25 degree having the other dimensions constant.

Zoomed view of static pressure over the hypersonic

inlet configuration with del 10 degree and beta (ramp angle) 25 deg when

experiencing Mach 1.8 is shown in Fig 5.18.

Zoomed view of static pressure over the hypersonic

inlet configuration with del 10 degree and beta (ramp angle) 25 deg when

experiencing Mach 1.8 is shown in Fig 5.18.

Zoomed view of velocity contours over the

hypersonic inlet configuration with del 10 degree and beta (ramp angle) 25 deg

when experiencing Mach 1.8 is shown in Fig 5.19.

5.7

HYPERSONIC INLET CONFIGURATION

WITH DEL 10 DEGREE

AND BETA (RAMP ANGLE) 30 DEG GENERATED IN GAMBIT

The next set of sytudy is done by keeping the del

angle constant and varing the ramp angle from 25 degrees to 35 degrees with a

variation of 5 degree at each case. The Fig 5.17 shows the basic variation of

ramp angle which is started at 30 degree having the other dimensions constant.

5.8 HYPERSONIC INLET

CONFIGURATION WITH DEL 10 DEGREE AND BETA (RAMP ANGLE) 35 DEG GENERATED IN GAMBIT

The next set of sytudy is done by keeping the del

angle constant and varing the ramp angle from 25 degrees to 35 degrees with a

variation of 5 degree at each case.

The Fig 5.17 shows the basic variation of ramp

angle which is started at 35 degree having the other dimensions constant.

Zoomed view of pressure contours over the

hypersonic inlet configuration with del 10 degree and beta (ramp angle) 35 deg

when experiencing Mach 1.8 is shown in Fig 5.24

Zoomed view of velocity contour over the hypersonic

inlet configuration with del 10 degree and beta (ramp angle)35 deg when

experiencing Mach 1.8 is shown in Fig 5.25

From all the above study it been found that having

the beta angle of 25 degree gives a better compression ratio with less

separation.

The values obtained from the simulation results are

tabulated in the Table 5.1 and 5.2.

Hence, while varying (delta) the inlet angle, it has been observed

that (increased in the delta) angle creates a formation of local shock and

thereby causes compression. Whereas, at the same time greater the increase in

delta angle the reflection and the interaction of the shocks degrades/distorts

the uniformity of the flow and thereby reduces compression which is evident

from the above table.

Increase in delta angle =decrease in static pressure

Therefore based on the required design velocity at

the chamber, the optimum one can be selected. Here, delta 10 degree can be

selected because it achieves maximum compression and maximum velocity. So delta

10 degree is suitable for supersonic flows.

The above table 5.2 shows the optimum pressure and velocity values from

the pressure and contour plots

6.

CONCLUSION

The purpose of this paper was to determine at which

angle scramjet engine will achieves the maximum compression and maximum

velocity by eliminating the combustion instability of the propulsion system

while performance is maintained in the same flow path at the higher. And to

define how, it could be accomplished. Hence a scramjet engine was then modelled

in GAMBIT and analysis was carried out in FLUENT for the same with different

models.

It was found that the delta angle 10 degree was

feasible as it matched the theoretical values with CFD values. By this analysis

we can conclude k-epsilon turbulence model exactly simulates the flow field

characteristics in Supersonic and hypersonic condition in capturing shocks at

leading edges and shock trains in the isolator and etc.

In future

scope in the design of this particular scramjet engine, we can varying the Mach

number and varying ramp to determine the appropriate inlet performance.

Preliminary results revealed that ramp angle of 25 degree shows good

performance relative to the other configurations.

FUTURE SCOPE

Ø Curran, Edward T.Scramjet Engines: The First Forty Years. Journal of

Propulsion and Power, Volume 17, No. 6, November-December 2001.

Ø Fry, Ronald S.A Century of Ramjet Propulsion Technology Evolution.

Journal of Propulsion and Power, Volume 20, No. 1, January-February 2004:

27-58.

Ø Waltrup, Paul J. Upper Bounds on the Flight Speed of Hydrocarbon-Fuelled

Scramjet-Powered Vehicles. Journal of Propulsion and Power, Volume 17, No. 6,

November-December 2001: 1199-1204.

Ø Builder, C.H. On the Thermodynamic Spectrum of Airbreathing

Ø Propulsion AIAA 1st Annual Meeting, Washington, D.C., June 1964.AIAA

Paper 64-243.

Ø Heiser, William H., David T. Pratt, Daniel H. Daley, and Unmeel B.

Mehta. Brief Description of the HAP Software

Ø Zucrow, Maurice J., and Joe D.

Hoffman. Gas Dynamics. Vol. 1. New York: John Wiley & Sons, Inc., 1976.

Ø Anderson, Jr., John D. Modern

Compressible Flow with Historical erspective. 2nd Ed. New York: McGraw-Hill

Company,

1990

Ø Analysis And Design Of A Hypersonic Scramjet Engine

With A Starting Mach Number Of 4.00 By Kristen Nicole Roberts. August 2008

Comments

Post a Comment